Engineering & Technical

Team Structure

Tailored Solutions. Built for Your Field.

MISSION:

To provide end-to-end engineering and design services for agricultural equipment manufacturers, from advanced simulation and concept development to production-ready mechanical CAD and drafting, specifically engineered for the demanding conditions and regulations of the Canadian market.

Core Value Proposition:

Leveraging a hybrid team of licensed Canadian professional engineers (P.Eng),

in-training engineers (E.I.T.), and a skilled overseas team in Mexico to deliver high-quality, cost-

effective, and certiable engineering solutions.

END TO END ENGINEERING

✳︎

SIMULATION TO PRODUCTION

✳︎

P.ENG LED & CSA COMPLIANT

✳︎

BUILT FOR CANADIAN CONDITIONS

✳︎

END TO END ENGINEERING ✳︎ SIMULATION TO PRODUCTION ✳︎ P.ENG LED & CSA COMPLIANT ✳︎ BUILT FOR CANADIAN CONDITIONS ✳︎

Canadian-Based Team (P.Eng & E.I.T.)

-

Project Leadership, Professional Oversight, and Canadian Compliance.

-

Responsibilities: Hold ultimate legal and ethical responsibility for engineering designs. They

seal and sign off on nal drawings and calculations for public safety and regulatory

compliance. They are the primary point of contact for clients on all critical engineering

decisions.

Focus Areas: Structural integrity and weldment design, machine safety (CAN/CSA),

hydraulic system pressure vessel compliance, geotechnical aspects for tillage equipment,

and signing off on Final Design Reviews.

-

Responsibilities: Perform the hands-on engineering analysis, simulation setup, detailed

calculations, and prototype testing support. They work under the direct supervision and

mentorship of a P.Eng.

Focus Areas: Running FEA simulations, creating kinematic models, managing test data, and

preparing technical documentation for P.Eng review.

Mexico-Based Engineering & Design Team.

Here, creativity meets opportunity. Whatever you're building, we're here to help you take the first step with confidence. Driven by curiosity and built on purpose, this is where bold thinking meets thoughtful execution. Let’s create something meaningful together.

-

Execution, Detailing, and Scalable Production Support.

-

Responsibilities: Execute the detailed mechanical CAD design, create comprehensive

manufacturing drawings (GD&T), manage the Bill of Materials (BOM), and perform CAD

automation and customization tasks. They work from the concepts, specications, and

under the direction of the Canadian team.

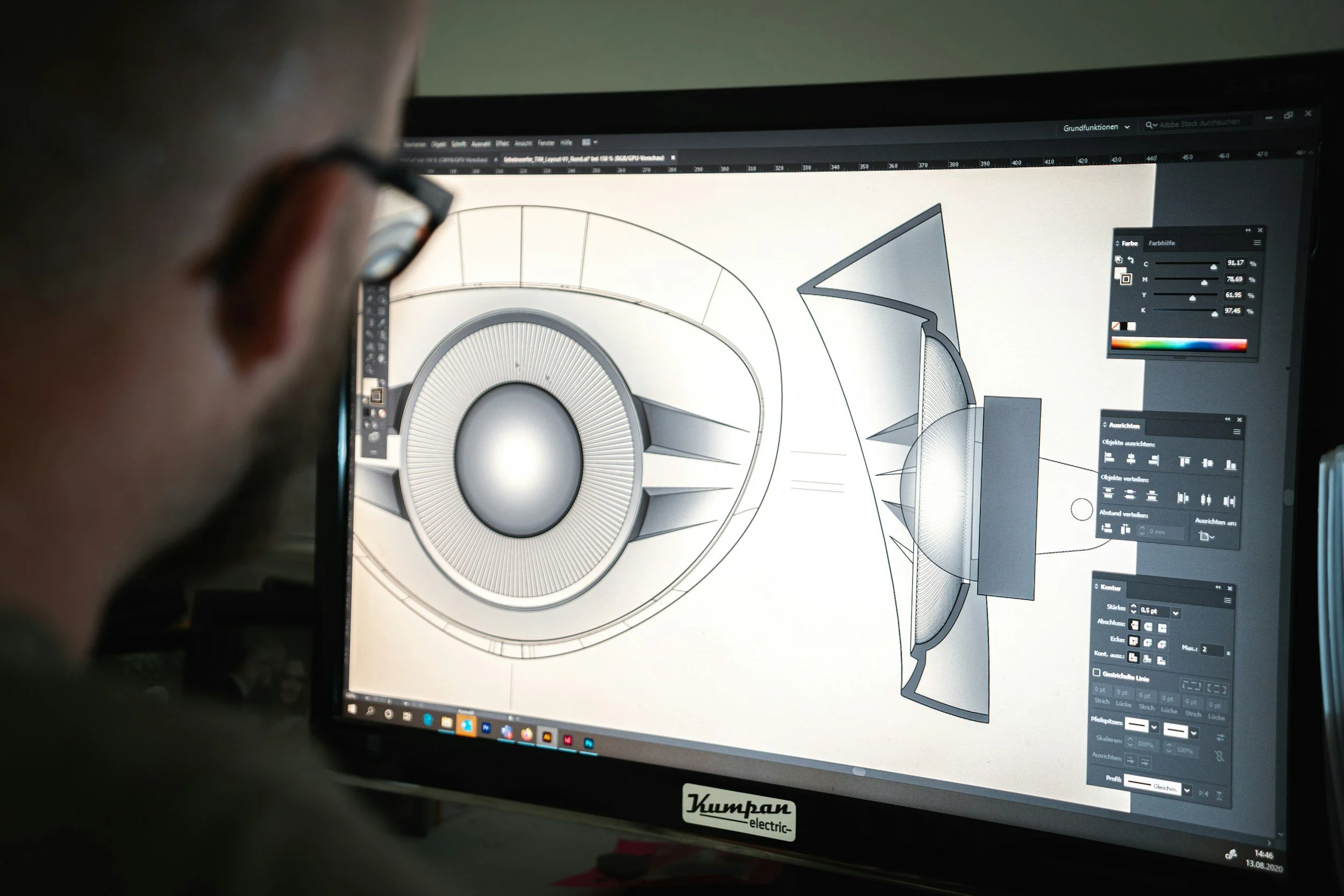

Focus Areas: 3D parametric modeling (SolidWorks, Inventor, Creo, Onshape, etc.), sheet

metal design, weldment detailing, complex assembly management, and creatingfabrication-ready drawings.

Technical Workow: From Simulation to CAD Drafting.

The engineering process is a seamless, iterative pipeline between the teams.

PHASE 1:

Concept & Simulation (Led by Canadian E.I.T./P.Eng)

-

The Canadian team, in close consultation with the client, defines the product requirements: performance targets, material specs, budget, and most importantly, Canadian standards (e.g., CSA M Series for agriculture, OSHA-equivalent safety regulations).

-

A basic 3D model is created, often starting in Canada, to establish the core architecture.

-

E.I.T.s use software like ANSYS, SolidWorks Simulation, or Abaqus to perform:

Static & Dynamic FEA: Analyzing stress, strain, and fatigue on frames, booms, and linkages under extreme Canadian loads (e.g., hitting a rock at depth, heavy snow loads on storage structures).

Kinematics & Dynamics: Simulating the motion of complex linkages (e.g., planter row units, combine headers) to ensure no interference and optimal movement.

CFD (Computational Fluid Dynamics): Modeling air flow for cleaning systems in combines or grain dryers.

PHASE 2:

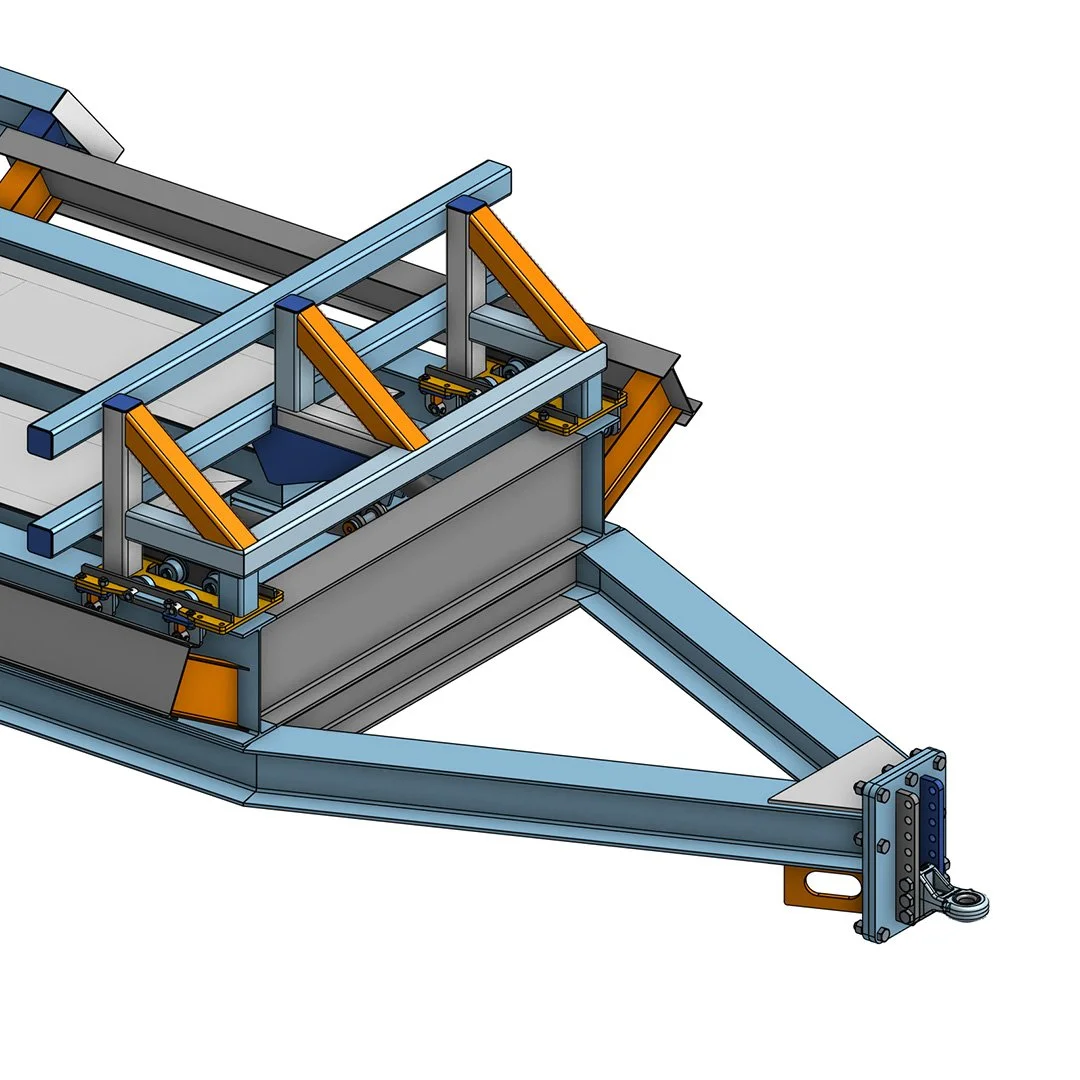

Detailed Design & Drafting (Executed by Mexico Team, Reviewed in Canada).

-

The validated concept model and simulation results are transferred to the

Mexico team via a controlled data management system (e.g., PDM/PLM).

-

The Mexico team develops the full, detailed assembly. This includes:

Designing intricate sheet metal brackets and shrouds.

Creating hydraulic and electrical routings.

Designing weldments with proper preparation details.

Selecting standard components (bearings, cylinders, fasteners).

-

They generate all manufacturing drawings.

Apply Geometric Dimensioning & Tolerancing (GD&T) to ensure parts are manufactured

correctly and assemble properly.

Create detailed Bills of Materials (BOM) with part numbers, descriptions, and materials.

-

The Mexico team provides critical input on

manufacturability, suggesting design changes to simplify fabrication, reduce costs, and improve

assembly.

PHASE 3:

Validation & Sign-off (Led by Canadian P.Eng)

-

The Canadian P.Eng and E.I.T. conduct regular design reviews of the work coming from Mexico, using mark-up tools and video conferencing.

-

The Canadian team runs final simulations on the detailed model to confirm it still meets all performance and safety criteria.

-

The P.Eng performs a final comprehensive review of all critical calculations, drawings, and the design package. Once satisfied, they apply their P.Eng stamp to the final assembly and key component drawings, taking legal responsibility for the design's safety and integrity in Canada.

Specic Considerations for the Canadian Market

This company's structure is uniquely positioned to address Canadian needs:

Regulatory Compliance: The on-shore P.Eng ensures designs meet Canadian Standards Association (CSA) requirements and provincial regulations.

Environmental Durability: Designs are simulated and specified for harsh Canadian conditions: corrosion resistance (salty roads, fertilizer), extreme temperature operation (-35°C to +35°C), and UV degradation.

Local Manufacturing Practices: The Canadian team understands the capabilities and preferences of local fabricators and machine shops, ensuring drawings are practical and well-understood.

Agronomic Relevance: Designs are tailored for Canadian farming practices, such as large-scale, high-speed seeding and harvesting, and challenging soil types (e.g., clay in the Red River Valley, rocky soils in Eastern Ontario).

How the Integrated Team Addresses These Challenges

P.Eng: Professional Validation and Compliance Assurance

Our licensed Professional Engineers are integral to your project's success, providing:

Expert Validation: Rigorous review and analysis of structural integrity and safety-critical systems.

Standards Compliance: Ensuring all designs meet Canadian Standards Association (CSA) and other regulatory requirements.

Professional Sealing: Applying their P.Eng stamp to final designs, providing certified assurance of compliance and safety.

E.I.T. in Canada

Becomes the specialist in running the complex, application-specific simulations (DEM for manure, soil FEA interaction). They bridge the gap between the theoretical model and the practical field data provided by the client.

Overseas Team in MexicO

Excels at translating these engineered concepts into manufacturable and serviceable products. They have deep expertise in detailing heavy-wall weldments, specifying appropriate surface treatments for corrosion resistance, and creating clear, unambiguous drawings for the complex assemblies found in a TMR mixer or a pull scraper's ejection mechanism.

Summary

This company acts as a highly ecient, technically robust extension of its clients' engineering departments. It combines the professional accountability, regulatory knowledge, and client-facing leadership of Canadian P.Eng and E.I.T. professionals with the scalable, detailed-oriented, and cost-effective execution of a skilled overseas engineering team in Mexico. This hybrid model ensures that farm equipment manufacturers receive designs that are not only innovative and manufacturable but also legally compliant and safe for the demanding Canadian agricultural landscape.